The Integral Role of the Crankshaft of an Engine in Diesel Performance

Understanding the anatomy of a diesel engine is paramount for anyone involved in the automotive field, whether you're a dedicated mechanic, a spare parts supplier, or simply a curious enthusiast. Among the many components that contribute to the functionality and efficiency of a diesel engine, the crankshaft of an engine stands out as one of the most crucial elements. This article delves into the significance of the crankshaft, its role in diesel performance, and best practices for sourcing reliable parts.

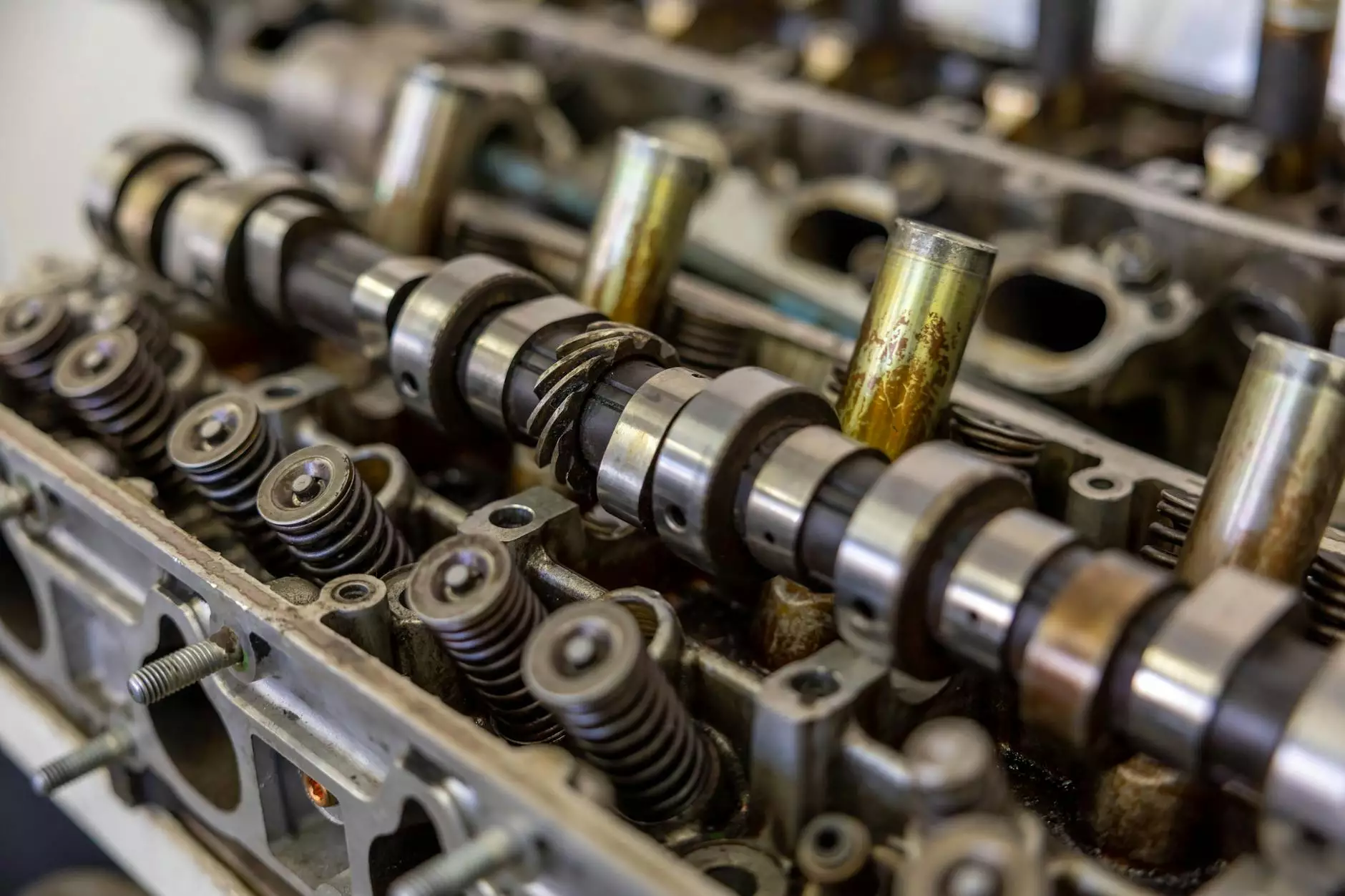

The Role of the Crankshaft in Diesel Engines

The crankshaft serves as the heart of the engine, converting linear motion into rotational motion. It is a fundamental component, responsible for transferring the energy produced during combustion to power the vehicle. The following aspects illustrate its importance:

- Energy Conversion: The crankshaft transforms the up-and-down movement of the pistons into a rotational motion that powers the vehicle.

- Durability and Strength: Constructed from high-quality materials, such as forged steel or cast iron, crankshafts are designed to withstand significant stress and wear.

- Balance and Vibration Control: A well-designed crankshaft helps maintain engine balance and reduces vibrations, ensuring a smoother ride.

Components of the Crankshaft

To appreciate the crankshaft of an engine, it is essential to understand its various components. Each part plays a specific role in the overall functionality:

- Crank Pins: Positioned at intervals along the crankshaft, these pins connect the crankshaft to the connecting rods, facilitating the transfer of power.

- Main Journals: These are thicker sections of the crankshaft that rest in the engine block, providing the shaft with support and stability.

- Counterweights: These are integrated into the design of the crankshaft to counterbalance the rotation, ensuring smooth operation by minimizing vibrations.

- Keyways: These slots allow for the attachment of other engine components, such as the flywheel and pulley systems.

How the Crankshaft Affects Engine Performance

The design and condition of the crankshaft of an engine directly influence engine dynamics and performance. Here are some ways through which the crankshaft plays a critical role:

1. Power Output

A precisely engineered crankshaft can significantly enhance the power output of a diesel engine. The efficiency with which the crankshaft converts crank angle movement into rotational speed is vital for optimizing acceleration and horsepower.

2. Fuel Efficiency

The balance and integrity of the crankshaft affect fuel combustion efficiency. A well-balanced crankshaft minimizes energy losses, thus improving fuel efficiency — a crucial factor in diesel engines that are often used for heavy-duty operations.

3. Longevity and Maintenance

Regular maintenance and timely replacement of worn-out crankshafts are essential for ensuring longevity. Any deformation or wear in the crankshaft can lead to catastrophic engine failures, highlighting the need for high-quality replacement parts.

Choosing the Right Parts for Your Crankshaft

When it comes to sourcing components for the crankshaft of an engine, quality should always take precedence. Here are some tips to help you make informed decisions:

1. Buy from Reputable Suppliers

Engaging with trusted suppliers such as client-diesel.com is essential for obtaining genuine and high-performance diesel engine parts. Always verify the supplier's reputation and customer feedback.

2. Understand Specification Standards

Make sure the crankshaft parts you purchase meet OEM specifications. This not only guarantees compatibility but also ensures that you are investing in parts that maintain the desired performance level.

3. Consider Aftermarket Options

Aftermarket parts can often provide more competitive pricing and may sometimes offer enhanced performance features. Conduct thorough research to determine the best aftermarket options available.

4. Regularly Inspect Existing Parts

Regular inspections can help you identify wear and tear early, preventing potential failures. Monitor your crankshaft for signs of damage and replace components as necessary.

Understanding the Manufacturing Process of Crankshafts

The manufacturing of a crankshaft involves several critical steps to ensure that the final product is robust and meets performance demands:

1. Material Selection

High-strength materials are selected for crankshaft production to endure the rigorous conditions within an engine. Typically, forged steel is the preferred choice due to its superior strength and fatigue resistance.

2. Machining and Forging

The crankshaft undergoes a process of forging and precise machining, where it is shaped and refined. This step ensures optimal tolerances and surface finishes, which are necessary for high performance.

3. Quality Checks

Robust testing protocols, including balancing and dimensional checks, are performed to verify that each crankshaft meets rigorous mechanical standards before reaching the market.

Common Issues with Crankshafts

While crankshafts are built to last, various factors can lead to failures:

1. Crankshaft Deflection

Deflection can occur due to excessive loads or high-performance modifications, leading the crankshaft to bend or warp, affecting its functionality.

2. Fatigue Cracks

Extended use at high RPMs can cause fatigue cracks, which pose serious risks of complete failure if not addressed promptly.

3. Oil Starvation

A lubricating failure can lead to inadequate oil supply to the crankshaft, causing overheating and subsequent damage.

Final Thoughts: The Crankshaft's Impact on Diesel Performance

In conclusion, the crankshaft of an engine is far more than just a mechanical component; it is a vital element that determines a diesel engine's overall efficiency, performance, and longevity. Understanding the critical role it plays enables engine professionals and enthusiasts alike to appreciate the craftsmanship involved in diesel engineering.

By choosing high-quality parts and establishing a routine maintenance schedule, you can greatly enhance your engine's performance and reliability. Prioritize quality over cost when sourcing components to ensure your diesel engine runs smoothly and efficiently for years to come.

Taking Action with client-diesel.com

When it comes to sourcing diesel engine parts, remember that client-diesel.com is your go-to destination. With a comprehensive range of high-quality products and a commitment to customer satisfaction, you can trust them to provide the parts that keep your engine operating at its best.