Unveiling the World of China CNC Machined Parts: A Comprehensive Guide

The realm of China CNC machined parts plays a pivotal role in the modern manufacturing landscape. With advancements in technology and a booming global marketplace, businesses are increasingly looking toward China for precision engineering solutions. In this article, we will explore the intricacies of CNC machining, the advantages of sourcing from China, and how you can leverage these parts to enhance your business operations.

The Basics of CNC Machining

CNC, or Computer Numerical Control, is a technology used to control machine tools with a computer. This innovative method of manufacturing allows for high precision and repeatability, which are critical components in modern industrial applications.

How CNC Machining Works

CNC machining involves the following key processes:

- Design: Utilizing CAD (Computer-Aided Design) software, engineers create a detailed blueprint of the part.

- Programming: This design is then converted into G-code, a programming language that CNC machines understand.

- Machining: The CNC machine follows the G-code instructions to cut, shape, and form the part from raw materials.

Applications of CNC Machining

CNC machined parts are essential across various industries, including:

- Aerospace: Components must meet stringent safety and performance standards.

- Automotive: Custom parts for engines, frames, and interiors are produced with high precision.

- Medical: Manufacturing of surgical tools and implants requires exceptional accuracy.

- Electronics: Precision components for devices and machinery that rely on detailed engineering.

The Importance of Sourcing from China

When it comes to sourcing China CNC machined parts, several factors contribute to the overall value of these solutions:

Cost-Effectiveness

One of the most significant advantages of sourcing from China is the cost-effectiveness. The lower labor costs and robust manufacturing capabilities allow companies to obtain high-quality parts at a fraction of the price compared to other regions. This can lead to massive savings in production costs, which is vital for competitive pricing in today’s market.

Superior Quality

Chinese manufacturers have significantly improved their quality standards over the past few decades. Many factories now adhere to international quality management systems, such as ISO 9001. When you choose the right manufacturer, you can be assured of receiving high-quality China CNC machined parts that meet or exceed your specifications.

Access to Advanced Technology

Chinese manufacturers are increasingly investing in state-of-the-art machinery and technology, enabling them to produce intricate designs and complex components efficiently. This advanced technology plays a crucial role in meeting the demands of various industries.

Deepmould: Your Go-To Source for CNC Machined Parts

At Deepmould, we specialize in providing high-quality China CNC machined parts tailored to the unique requirements of our clients. Our expertise in the field of metal fabrication ensures that every part we produce meets the highest quality standards. Here’s why partnering with us can give your business a competitive edge:

Custom Solutions

We understand that no two projects are the same. Our team of engineers works closely with you to develop customized machining solutions that align with your specific needs. Whether you require a small batch or mass production, we can handle it all.

Timely Delivery

In the fast-paced world of manufacturing, timing is everything. Deepmould is committed to ensuring that your China CNC machined parts are delivered on time, helping you maintain your production schedules and meet market demands.

Comprehensive Support

Our support doesn’t end at the sale. Deepmould provides ongoing assistance to our clients, ensuring that you have all the resources you need to effectively utilize our parts in your production processes. From technical support to after-sales service, we are here for you every step of the way.

The Benefits of Using CNC Machined Parts

Choosing CNC machined parts comes with a host of benefits that can significantly impact your business operations:

Enhanced Precision

CNC machining delivers unmatched precision, ensuring that every part meets exact specifications. This level of accuracy reduces the need for post-machining adjustments and minimizes waste, ultimately improving your production efficiency.

Scalability

CNC machining enables easy scalability of production. As demand increases, we can effortlessly ramp up production without compromising quality, which is essential for growing businesses.

Versatility in Materials

Manufacturers can use various materials for CNC machining, including metals like aluminum and stainless steel, plastics, and composites. This versatility allows businesses in different sectors to find suitable components for their products.

Quality Assurance in CNM Machining

At Deepmould, we prioritize quality assurance throughout the CNC machining process. Our rigorous quality control measures include:

- In-Process Inspection: Regular inspections during production to ensure consistent quality.

- Final Quality Checks: Comprehensive testing of final products to verify compliance with specifications.

- Customer Feedback: We actively seek feedback from customers to continuously improve our processes.

Choosing the Right Manufacturer for CNC Machining

Selecting the right manufacturer is crucial to ensuring high-quality outcomes for your CNC machined parts. Consider the following factors:

Expertise and Experience

Look for manufacturers with a proven track record in CNC machining. Explore their experience across different industries and evaluate their portfolio.

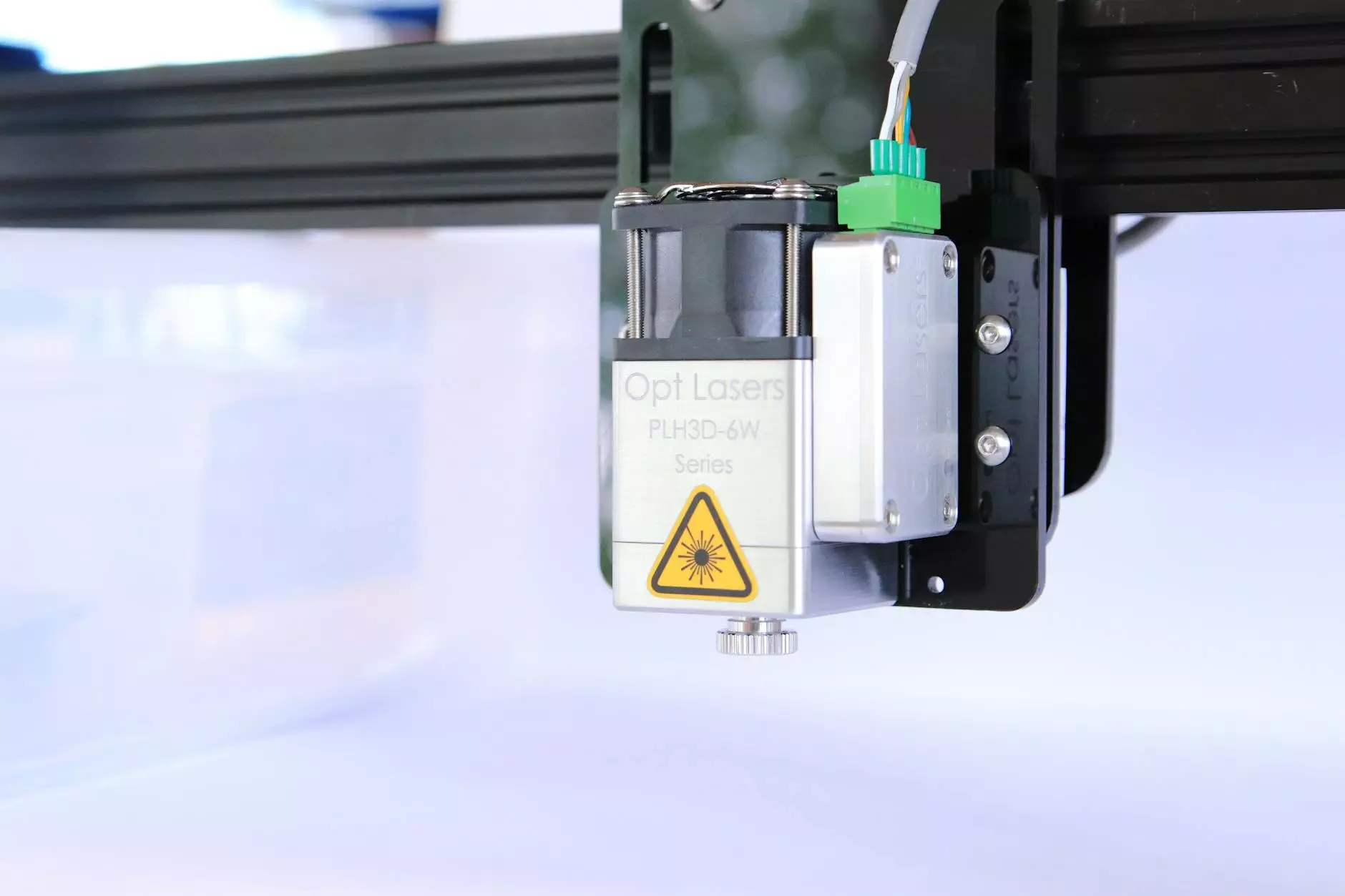

Technology and Equipment

Ensure the manufacturer is equipped with modern machinery and technology that can handle your specific machining requirements.

Quality Certifications

Check if the manufacturer has relevant quality certifications such as ISO 9001, which signify a commitment to quality standards.

Conclusion

In conclusion, the world of China CNC machined parts offers unparalleled opportunities for businesses seeking precision-engineered solutions. By leveraging advanced manufacturing technologies, competitive pricing, and the expertise of established suppliers like Deepmould, you can significantly enhance your operational efficiency and product quality. As you consider your next project, remember the critical role that sourcing high-quality CNC machined parts plays in your success.

For more information or to discuss your specific requirements, contact us at Deepmould. We are ready to assist you in taking your production capabilities to new heights!